Manufacturing Automation In a Post-Pandemic World

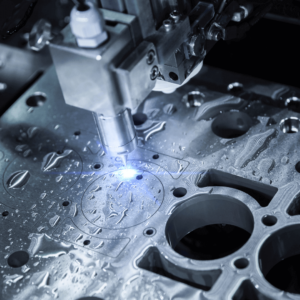

Manufacturing Automation is the use of engineering technology to automate various CNC machining processes. At Proform Manufacturing, this technology has revolutionized the way products are manufactured and has numerous benefits over traditional manual methods.

One of the main benefits of manufacturing automation is increased efficiency and speed. Automated machines can produce products at a much faster rate than manual labor, reducing production time and increasing output. This results in lean manufacturing, a significant increase in productivity, and improved quality control with reduced errors. This is critical in CNC machining, where accuracy is key in producers making many types of manufacturing parts.

Another key benefit we see at Proform regarding automated manufacturing is cost savings.

Automated machines do not require breaks or vacations as human workers do, and their performance does not decline over time. Robots and other advanced manufacturing tools and methods also use less energy than human labor, which reduces energy costs. Robotics and other automation technology reduce the need for manual labor, which reduces labor expenses. Human error is also decreased, and the ability to use applied science in industrial technology with the restriction of a controlled environment are other benefits of an automated system in the production process. We understand that skilled, experienced employees are required to manage this type of automation. One of the benefits of our staff at Proform is our experience in working with diverse types of precision machining technology.

system in the production process. We understand that skilled, experienced employees are required to manage this type of automation. One of the benefits of our staff at Proform is our experience in working with diverse types of precision machining technology.

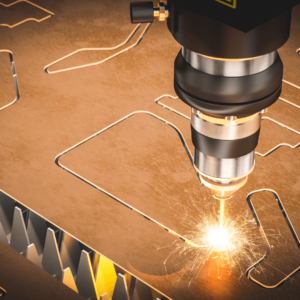

Manufacturing automation in CNC machining uses innovative technology and equipment to automate various processes involved in the production of goods.

The goal of manufacturing automation is to increase efficiency, reduce costs, improve product quality, and increase production speed. Automated manufacturing systems can range from simple machines that perform a single task to complex, integrated systems that control multiple processes across an entire production line. The use of sensors, control systems, and artificial intelligence (AI) technologies is becoming increasingly common in manufacturing automation, helping to further improve performance and efficiency.

At Proform, we seek to embrace this type of technology and evolve with time. As a proud American company, we desire to set the standard in balancing robust technology with our highly skilled employees to bring our clients unparallel quality and value. In addition, automated manufacturing systems offer greater flexibility and versatility. They can be programmed to handle multiple tasks, making it possible to switch between products with ease. They can also be adapted to meet changing market demands, making it possible to manufacture a wider range of products.

What is Flexible Automation?

Flexible automation is a type of manufacturing automation that allows for rapid changes in production processes, making it easier to produce a variety of products or respond to changing market demands. At Proform, we produce many types of product parts. The need for flexibility in our production processes helps with efficiency in the CNC machining process.

Unlike traditional automation, which is designed for a specific product or process, flexible automation systems can be reconfigured to handle different tasks or products.

This allows manufacturers to be more responsive to changing market conditions and customer demands, reducing the time and cost of switching production lines. Flexible manufacturing automation systems can include a range of technologies such as robots, programmable controllers, and conveyor systems that can be quickly reconfigured to handle different products or production processes. The use of modular components, standardized interfaces, and software-based control systems like CAD are also common in flexible automation, making it easier to change and adapt systems as needed.

Overall, flexible automation provides manufacturers like Proform with a more flexible and responsive manufacturing process. This helps us in 3 primary areas:

- Reducing Costs

- Improving Efficiency

- Remaining Competitive in a rapidly changing market.

What is Programmable Automation and its Benefits?

Programmable automation refers to the use of computer-based technologies and systems to control and manage manufacturing processes. This includes the use of programmable controllers, software-based control systems, and other digital technologies.

Programs like AutoCAD allow programmable manufacturing automation for companies to automate various tasks and processes involved in the production of goods.

These systems can be used to control and manage a wide range of manufacturing processes, such as assembly, testing, inspection, material handling, and packaging. Programmable automation systems can also be integrated with other systems and technologies, such as sensors, robotic systems, and machine learning algorithms, to further improve performance and efficiency. Proform uses the highest quality computer-aided assistance and the latest technology in precision machining regarding programmable automation.

Advantages of Programmable Manufacturing Automation

Keep in mind, this type of automation provides manufacturers with a flexible and efficient means of automating and controlling their production processes. The use of these computer-based technologies and software-based control systems allows smaller local manufacturers like Proform these main advantages:

- Reduce costs

- Improved efficiency

- Improved product quality

- Increased production speed

Innovative Manufacturing: The Future of Product Production

Innovative Automated Manufacturing is a vital component of both the local and global economy, and it has come a long way since the days of manual labor and simple machines. Today, innovative manufacturing processes and technologies are shaping the future of product production, making it faster, more efficient, and more flexible than ever before. Proform understands this, and over the past 38 years, we have embraced innovation in CNC precision machining.

One of the key drivers of innovative manufacturing is automation. Automated systems are becoming increasingly common in American-owned manufacturing environments, helping to improve efficiency and reduce costs. We do this without sacrificing quality and customer service.

Innovative automated systems can be programmed to handle multiple tasks, making it possible to switch between products with ease.

They can also be adapted to meet changing market demands, making it possible to manufacture a wider range of products. Precision machining is part of every industry, so it is essential that we get every detail correct.

Another important trend in innovative manufacturing automation is the use of advanced materials.

From metal fabrication to CNC plasma cutting, our services focus on improved performance and durability, making it possible to produce lighter and stronger products. This is particularly important in industries such as aerospace and defense, where accuracy and weight reduction are critical to performance and efficiency.

The use of digital technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), is also shaping the future of innovative manufacturing automation.

The IoT allows manufacturers to collect and analyze data from sensors and other sources, providing valuable insights into production processes and performance. AI algorithms can then be used to optimize production processes, reduce waste, and improve efficiency. Automation, advanced materials, digital technologies, and innovative manufacturing processes are helping local manufacturers like Proform to remain competitive in a rapidly changing market post-pandemic and meet the demands of a global customer base. Learn more about the Internet of Things here.

The IoT allows manufacturers to collect and analyze data from sensors and other sources, providing valuable insights into production processes and performance. AI algorithms can then be used to optimize production processes, reduce waste, and improve efficiency. Automation, advanced materials, digital technologies, and innovative manufacturing processes are helping local manufacturers like Proform to remain competitive in a rapidly changing market post-pandemic and meet the demands of a global customer base. Learn more about the Internet of Things here.

Innovative manufacturing is shaping the future of American product production, making it faster, more efficient, and more flexible than ever before.

Finally, innovative manufacturing automation processes, such as welding and plasma cutting, are allowing manufacturers to produce products in new and more efficient ways. 3D printers, for example, enable the production of complex shapes and geometries that would be difficult or impossible to produce using traditional manufacturing methods. This is helping to reduce production time and costs, while also increasing product quality.

Challenges With New Age Manufacturing Automation Techniques

Despite the many benefits of automation at a manufacturing facility, there are some challenges that need to be addressed. One of the main challenges is the high initial investment required to set up automated systems. This can be a barrier for small businesses, who may not have the financial resources to make the investment. One robotic arm in an industrial automation factory or facility can cost upwards of $400,000.

Another challenge is the skill level required to operate and maintain automated manufacturing systems. Employees need to be trained in the use of automated systems, and specialized maintenance personnel may need to be hired.

In today’s economy, it may be a challenge for human resources and business leaders to find skilled workers to manage new-age manufacturing automation systems quickly.

The manufacturing industry is changing in such a way that automated manufacturing technology is becoming more competitive. Additionally, automated systems can become outdated quickly, requiring frequent updates and upgrades.

Hard automation (also known as fixed automation) in a type of manufacturing automation system may require both mechanical engineering technology along with a strong human skillset for oversight.

Our leadership and team at Proform Manufacturing consider each of these challenges. We take a balanced approach to hiring and training the best people, while simultaneously investing in new technologies.

Is Automated Manufacturing the Right Choice for Your Facility?

In conclusion, automated manufacturing is a powerful tool that can greatly improve manufacturing efficiency and productivity. While there are challenges that need to be addressed, the benefits make it an attractive option for local companies looking to remain competitive in today’s global market. At Proform, we take pride in our American roots as a precision manufacturer. We strive for excellence and realize that it takes a balanced approach between man and machine. To learn more about the Proform Manufacturing difference, Contact Us