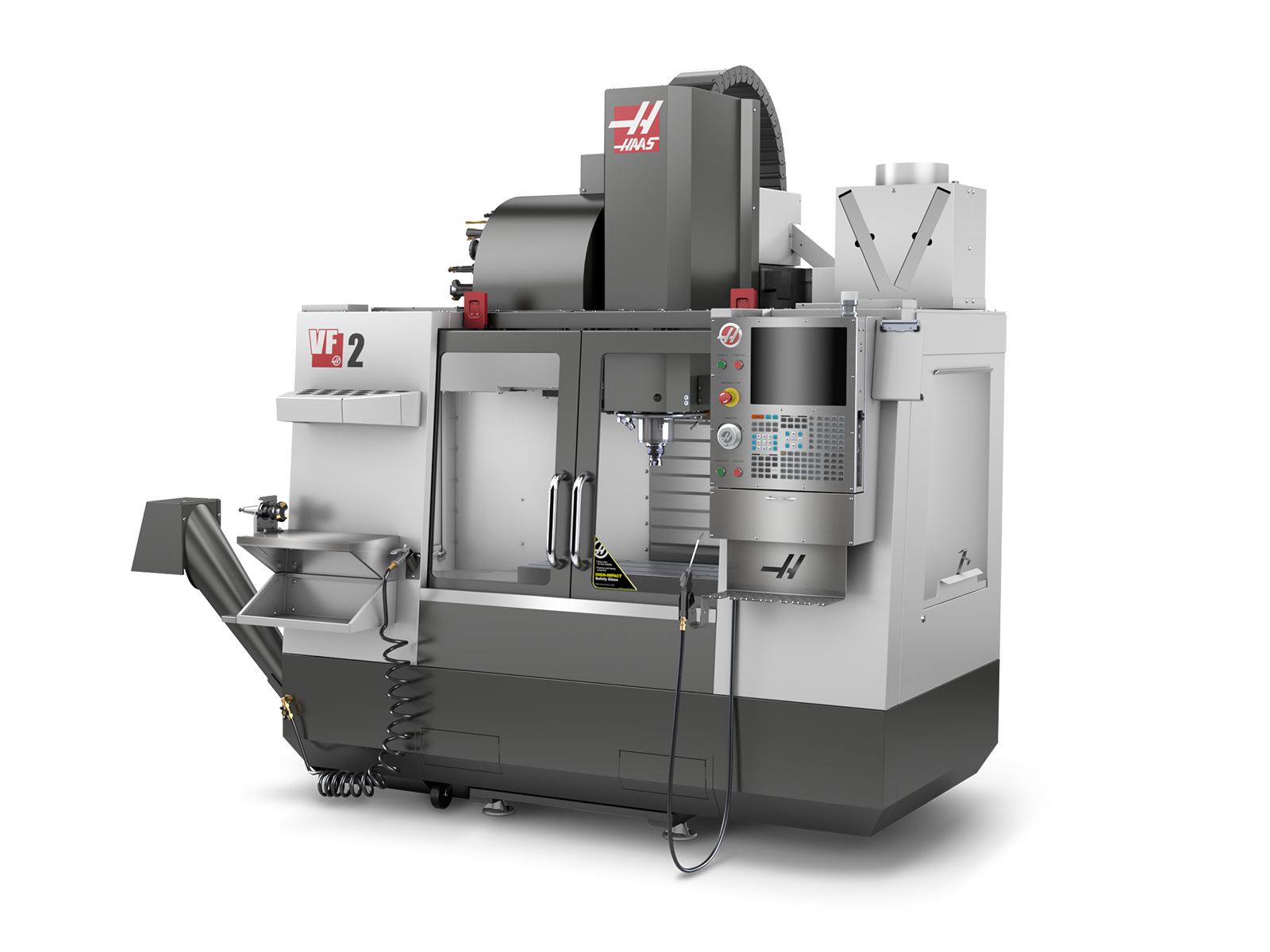

Proform utilizes CNC mills, lathes, multi-axis machines and Swiss-styled machines that accommodate a diverse range of projects; from small batch and custom projects, all the way up to large scale production runs of high volume parts. We have a wide range of capabilities that enables us to:

Proform’s design and engineering services encompass everything from conceptualizing and designing custom parts to optimizing manufacturing processes as well as building prototypes, all with a focus on precision and efficiency.

Have an idea for a new or improved part but struggling to bring it to life? At Proform our skilled engineers can help create or refine designs, and suggest process improvements to ensure manufacturability and optimize production.

No prints, no problem. At Proform, reverse engineering of old or current parts starts with the creation of a 3D model and production print. As applicable, a 3D print can also be generated for product testing purposes. Using this process, we have successfully reversed engineered parts for both small batch production and short lead times, as well as larger scale production runs.

We work closely with our customers to ensure that parts and products are easy and cost effective to manufacture. This includes analyzing designs and parts to create upgrades or replacements that offer better functionality within a given budget.

Proform undertakes industrial repairs using both additive as well as subtractive manufacturing processes. This includes replacing worn out or damaged parts, as well as reverse engineering to create replacement parts or designs for obsolete or damaged equipment when originals are unavailable. We understand that some repairs are time sensitive and have built a strong reputation for rapid turn around times to minimize downtown and meet customer requirements.

Prototyping manufacturing gives three dimensional substance to a design to determine how it works in the real world. Prototyping helps designers and creators:

At Proform, we offer a wide range of metal fabrication services to a diverse customer base.

Our core services include:

We offer our fabrication services to a wide and growing range of industries including:

We provide sub-assemblies and metal fabrication solutions for trailer manufacturers, including gates, hitches and structural elements.

We have designed and built of fabricated parts for material handling that includes components for conveyors, racks and handling equipment.

We are able to provide a wide range of sub-assemblies as well as fully assembled hand rails and other products.

We cater to various industrial sectors to offer customized solutions for appliances and equipment.

Heat treating raises the core temperature of the metal, in effect altering its molecular structure. Changing the molecular content alters the physical properties of the metal to attain a specific advantage. The heat-treating process achieves new properties in the metal. For example, we can heat treat metal to harden, increase strength, or reduce wear on the component.

We use a controlled heating and cooling process to realign the molecules to keep the strength but eliminate the metal from becoming brittle. Fabricators also use heat treating to manipulate metal during the fabrication process. Other characteristics heat treatment can modify are improving machinability, changing electrical or magnetic conductivity, and increasing hard or softness values.

For rust protection, paint and primer provide decorative protection that often safeguards parts from external elements such as weather conditions. The paint and primer surface treatment process comes in almost any color imaginable. Therefore, it creates an aesthetically pleasing surface finish, unlike other metal finishing products.

This method generally uses a liquid spray of baking varnish or self-drying paint. Varnish has a thin layer usually suitable for precision parts. Using a spray ensures an even coating of paint over the part’s surface. The finished product is a smooth painted finish of any color that looks and feels however you choose for your project specifications.

This acid bath is often best used on stainless steel. Passivation removes free carbon molecules from the surface of a metal fabricated part. Meaning the surface treatment process is used to rust-proof a machined part. Another form of a conversion procedure, this method changes the top layer.

Once again, dipped into a specialized acid bath, we change the chemical makeup of the original base metal. The process provides a protective coat around the part. The final metal part gains the desired benefits that the original metal does not naturally possess. In this case, we are gaining a rust-proof resistance to natural environmental conditions.

When working with metals, consider black oxide to achieve a blackened firm protective surface. This conversion coating minimizes reflective metal properties and provides mild corrosion resistance. Appropriate for ferrous materials, including steel, stainless steel, copper, brass bronze, cast iron, and copper alloys.

You get a black oxide layer by dipping the part into various chemical treatment tanks and a sealant. A benefit of this coating on precision parts is that it has no significant dimensional measurements. Therefore, your part retains the exact measurements within approximately one µm, or roughly 0.001 mm thick.

When you need aluminum hardened, anodizing is the correct process. Anodizing strengthens the element to a 9 out of 10 on the hardness scale. This metal finishing process is mainly for aluminum and aluminum alloys. First, the fabricated part goes into a charge tank for an electrically charged acid bath. The bath removes surface rusting.

Next, oxidizing builds a black or transparent oxide film. A color coating may also be used but is less popular due to color inconsistency. Surface anodizing creates a new stronger part that is less prone to scratching and seals it from outside elements. The final result is a hardened, long-lasting part that preserves its natural metal luster.

Powder coating is a typical metal finishing process that supplies an additional chemically inert coating to the outer layer. Dipping the part into an acid bath gives the metal a static electric charge. The powdered paint is then blown and evenly distributed over the surface.

The powder is a mixture of resins, pigment, fillers, metal fragments, and curing agents. This mixture sticks only to where the part is chemically charged. After coating, the part bakes at 400 degrees. The paint melts and then cools, forming a durable coating and painted finish. This coating technique increases wear resistance and corrosion protection while being aesthetically pleasing.

Sandblasting strips the surface of a part. Using sand as a powerful abrasive, a sandblast gun forces it to eliminate the finish or texture from the piece. This method is also used as another deburring process as it changes the appearance of the original part. The coating textured layer improves the durability of the metal part.

Also, sandblasting removes harmful contaminants in an efficient cleansing process. Removing dirt and oils is ideal before a welding process. Depending on the geometric shape of your part, it also penetrates otherwise challenging, hard-to-reach areas for decontamination. The finished product is a component with a smooth and shiny finish.