5 Axis CNC Machining

5 axis machining is subtractive manufacturing raw material down to the desired finished product, using tools that mill or turn the material along 5 different axes. Our 5 axis CNC (computer numerical control) machines use multiple angles and subtractive processes to form intricately designed parts or pieces for the most delicate industries. The use of multiple axes, on both the tool and the block of material, is controlled by a sophisticated computer. This process efficiently provides the most complex and geometric parts through cutting tools that rotate as the material rotates on a holding device.

The development of the first CNC machine began in the 1940s when John T. Parsons used a numerical system to build helicopter rotors. From there a team of researchers at MIT used Punch Tape to program a code to precisely produce the desired designed parts. Computer-Assisted Manufacturing (CAM) came into the picture in 1959 when manufacturers could draw a design on a computer to feed a milling machine the exact coordinates and instructions on how to create a piece from a block. MIT gets the credit for the first fully computer-controlled milling machine!

Why 5 Axis Machining?

5 axis machining is when precision meets speed and motion. Imagine a cutting tool that can freely handle machining from all angles without operators having to constantly move and shift material. 5 axis machining eliminates manual rotation as the machine does the work precisely, by itself. That leads to better accuracy, higher production rates, and greater ability to manufacture larger, more complex parts, all in a faster time than other CNC machines.

3 axis machining, in comparison, is best for mostly flat products and pieces. Blocks are fixed onto a machine bed, while operators have to reposition the blocks for unconventional shapes and deeper cavities. This allows room for slight variances or rough edges that come at the hands of machinists, as well as machinists will take longer to accurately finish a product. 5 axis machining offers more precise, smooth surface finishes and dimensional stability for complex shapes and parts.

What are the 5 Axis in Machining?

Axes are designated letters that determine the direction a cutting tool must go, which for 3 axis and 5 axis CNC machines are…

- X axis (left to right)

- Y axis (top to bottom/up and down)

- Z axis (front to back/in and out)

- A axis (rotation around X axis)

- B axis (rotation around the Y axis)

Whereas the 3 axis machines depend on X, Y, and Z axes to compute the level of detail it needs, 5 axis machines use those 3 axes plus the A axis and B axis to rotate the tool and/or the block of material.

Types of 5 Axis CNC Machining

There are three types of CNC machining strategically involving a 5 axis CNC machine: indexed machining, continuous machining, and mill-turn machining.

Indexed CNC Machining

With an indexed CNC machine, also known as 3+2 axis machining, cutting tools only move continuously along three axes, while the table that holds the block of material will swivel in two rotational axes. 4 axis machining, acting as 3+1 machining, is where the spindle tool moves on 3 axes (X, Y, and Z axes) and a table holding the material moves and rotates on the fourth axis, the A axis. The rotation makes the 4 axis CNC machine produce faster than a 3 axis, but still involves some manpower to reposition the material. Indexed machining is still more precise and efficient than a 3-axis machine, but not as fast as a tool on 5 axes because the tool intermittently touches the block piece.

Continuous CNC Machining

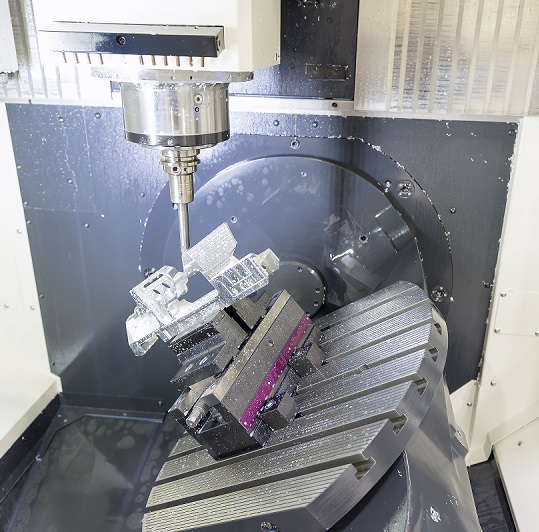

A continuous 5 axis machine lets the cutting tool move on all five axes to ensure that the tip of the tool maintains the same point on the block. The cutting tool maintains engagement with the material at all 5 machining angles even when the holding table moves, maximizing use of the entire workstation with much less manpower involved.

Mill-Turn CNC Machining

Mill-turn machining is when a block has the continuous ability to rotate while the cutting tool mills the block from all five rotational axes, becoming a hybrid machine that is by far the most efficient type of CNC machining.

CNC Turning and CNC Milling

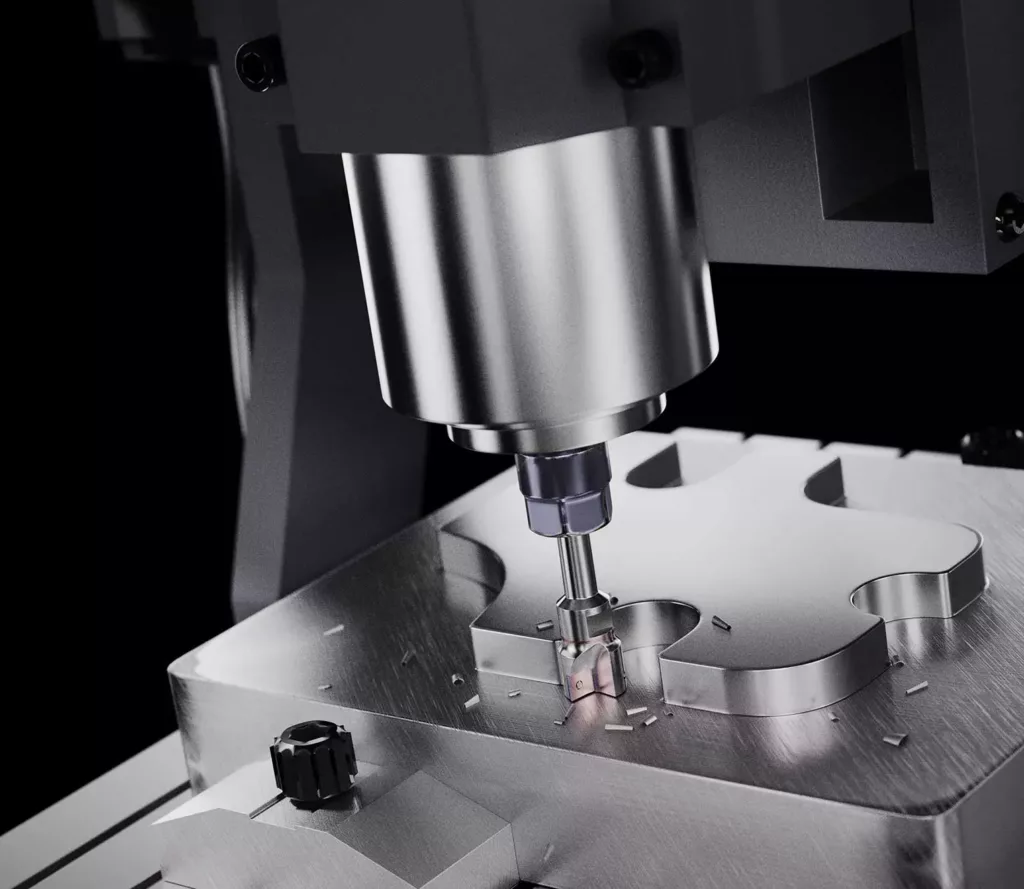

5 axis CNC machining consists of milling and turning processes. A CNC milling machine uses rotating precision tools on various axes while holding the block of raw material in place. The milling machine receives the code to remove material from the solid block on the five axes whether or not the block moves with the cutting tool. The milling process can handle more complex detail in a part or product whereas turning is optimal for producing round or cylindrical shapes.

There are multiple ways that a milling machine can cut a block of material, but the two most distinct are conventional and climbing. Conventional milling is when the tool cuts in the opposite direction of the block. Cutting in the opposite direction causes the friction that quickly shaves down the block. Climb milling involves the tool rotating with the direction of the block’s feed, thinly cutting the block in less wear and tear than the conventional method.

There are multiple ways that a milling machine can cut a block of material, but the two most distinct are conventional and climbing. Conventional milling is when the tool cuts in the opposite direction of the block. Cutting in the opposite direction causes the friction that quickly shaves down the block. Climb milling involves the tool rotating with the direction of the block’s feed, thinly cutting the block in less wear and tear than the conventional method.

While CNC milling machines rely on high precision cutting tools, CNC turning relies on the involvement of rotating the potential part on various axes to feed the cutting tool at high speeds. Turning centers have taken the old lathe and applied CNC technologies to churn out parts more efficiently. The turning tool is typically mounted or fixed so that it can produce deep cavities. The turning tool performs several different operations to rotate material into the desired part – turning, parting, chamfering, knurling, drilling, facing, and boring.

Turning is where the tool removes material from a block along a linear axis with the workstation. It typically cuts down on the diameter of a cylindrical part. Parting is a lathe tool that cuts a piece into two at specific machining angles. Chamfering tools are used to eliminate the sharp edges off a corner of a piece. Knurling creates patterns of straight, angled, or crossed lines on parts. The drilling operation tool removes material from the inside of a block. A facing tool cuts a flat surface that is perpendicular to the block’s rotational axis. A boring tool enlarges holes that have already been drilled to create even higher precision.

Proform Manufacturing’s 5-Axis Machining Capabilities

Proform American Manufacturing prides itself in manufacturing the best in precision parts. We are experts at providing any manufacturing needs, from small batch medical parts to mass production parts to large construction weldments. We use the latest in CAD and CAM technology with 5 axis machining and some of the largest variety of equipment necessary to fulfill any job. We have over 30 cutting machines in-house that create parts out of hard and soft metal, from aluminum to carbon steel. Our team is skilled in a multitude of fabrication services from start to finish.

Contact Us to learn more about our Precision 5 Axis Machining or other Manufacturing Capabilities.