Proform Manufacturing’s Fabrication Services

Our fabrication services provide precision metrics and project scope details to your metal fabrication service needs. Proform’s fabrication services maintain mathematical accuracy during the production run with an acute variance of + or – .005 of an inch. Trust Proform American Manufacturing to machine your important components when you have a detailed metal part that needs manufacturing. We custom machine parts that operate under extreme stress and provide ultimate performance.

Proform American Manufacturing specializes in two forms of metal fabrication services; Machining and 3D Printing. Machining takes a raw metal block and etches it away to sculpt the correct shape and precise measurements. Metal fabrication by machining can create very complex geometric forms in design. Similarly, 3D printing also creates intricate components by building metal in layers. It is a method of making the part layer by layer instead of removing excess material.

Proform custom metal fabrication produces both small and large parts alike. Our metal fabrication shop capability lies not only in precision parts but also in industrial metal fabrication and structural metal fab services. Medical devices and electronics often use Swiss-style metal fabrication. Whereas large or massive-scale projects often use industrial or structural metal fabrication. Whether machining or 3D printing, Proform American Manufacturing delivers a perfectly manufactured product every time.

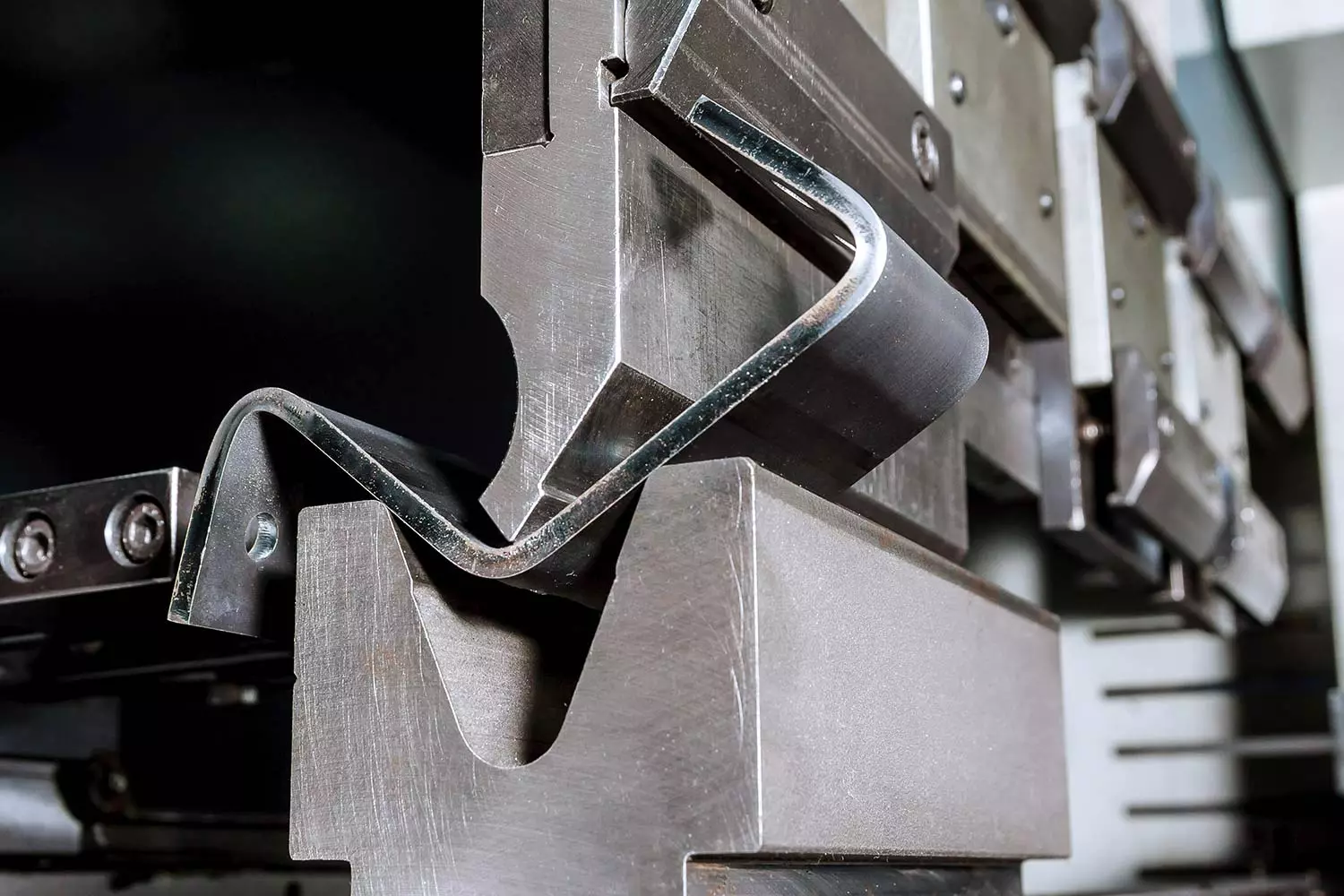

Proform American Manufacturing specializes in sheet metal forming and industrial iron fabrication. We process iron and steel fabrication. Our iron fabrication methods use bending, forming, rolling, cutting, and punching to achieve the desired product. The workers at Proform are skilled in the different carbon content of multiple categories of steel and how their properties affect the fabrication process as well as the outcome of the project.

Our mechanical engineers help you choose the correct raw material for the job, including environment, strength or flexibility, conductivity, corrosion resistance, and user behavior. We think through the details that set your production metal parts above the competition. High-quality components begin with the correct raw material.

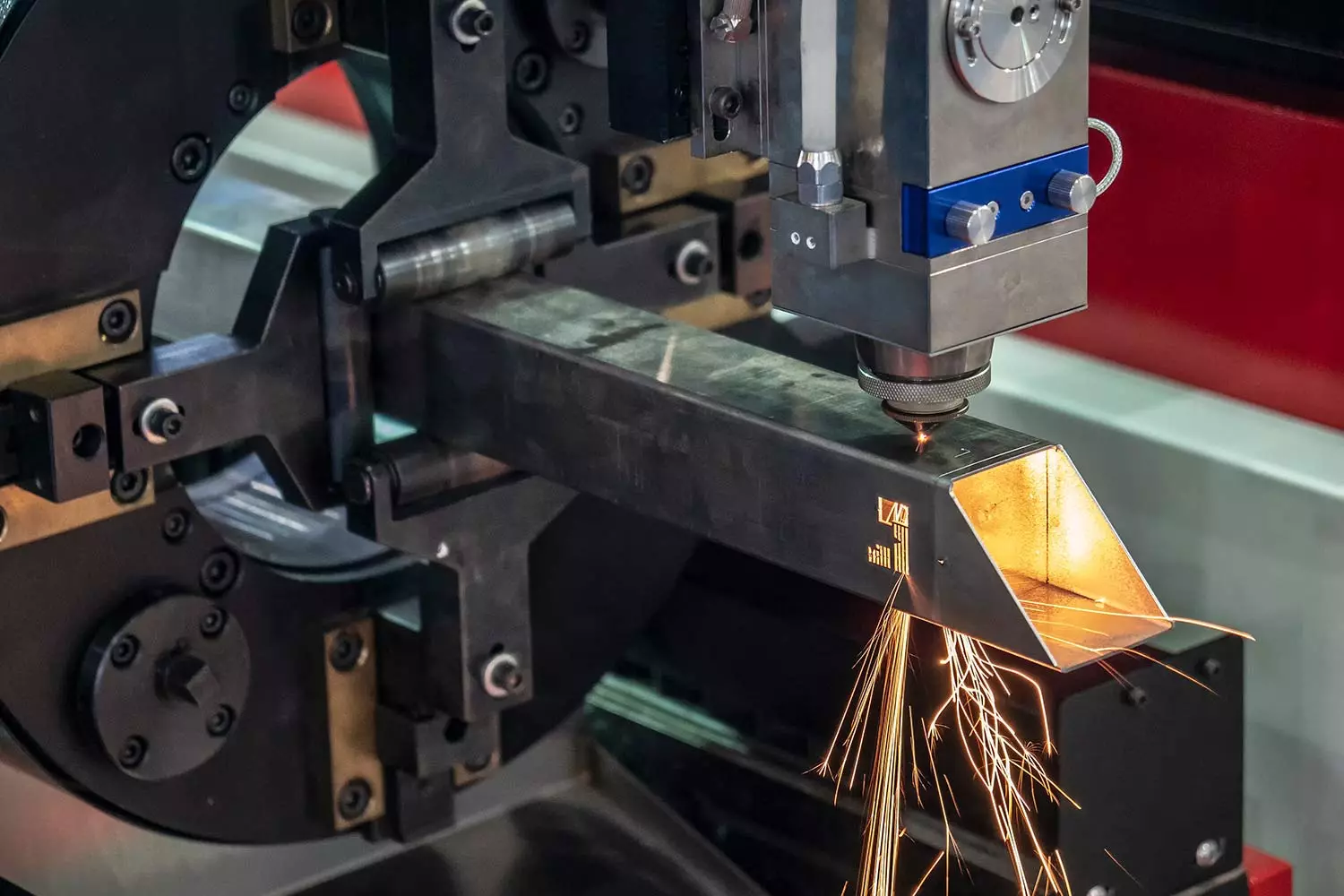

Our advanced and modern cutting equipment grants us the ability to perform many different cutting techniques with all types of metal materials. We operate everything from hand tools to fully digital automated cutting machines. Furthermore, we run multiple cutting and tooling actions simultaneously. New technology is continually making advancements in metal cutting techniques.

In metal cutting, each tool performs its own specific purpose. We master our cutting tools and optimize their effectiveness in the fabrication process. We cut the most refined and complicated shapes to the largest and most straightforward forms. Cutting is all about getting the exact shape and measurements to meet your particular needs.

Plasma provides an advanced and high-speed form of precision cutting. Our plasma cutting machines concentrate a focused narrow stream of ionized gas as a specialized thermal cutting technique. Plasma cutting is best suited for sheet metal cutting. Still, it has various other fabrication cutting possibilities, such as tube and pipe cutting.

CNC plasma technology controls the cutting path allowing precise controls over the cut quality. Cutting with plasma has adaptability, speed, and precision quality assurance all in one. Proform American Manufacturing uses plasma cutting to penetrate steel, stainless steel, aluminum, copper, brass, and non-ferrous metals up to 3/4 inch thick. Structural steel and high-grade carbon steel often use plasma cutting services for their quality cut.

Our welding services include multiple welding techniques. Different techniques provide better options based on the weld style and materials used. In short, no one method works for all materials. Our artisan’s competency lies in MIG welding – Gas Metal Arc Welding (GMAW), TIG welding – Gas Tungsten Arc Welding (GTAW), Flux Cored Arc Welding (FCAW), and Stick – Shielded Metal Arc Welding.

We have a large variety of metals and experience in what methods yield the best results. Outcomes are often dependent on material selection as well as part specifications and desired results. Whether you need minute precision welding for micro parts or large-scale weldments for structural engineering, Proform American Manufacturing has a vast portfolio of success.