Benefits of Customized Iron Fabrication Services

When choosing custom fabrication, you control tailoring the metal product to fit the minute differences that raise your product one step above the competition. It’s those little details that set us apart from our counterparts. We’re happy to help you achieve them. Consequently, you’ll also meet your client’s needs at a higher level.

Custom metal fabrication allows you the freedom to optimize the benefits of the material and processes chosen for manufacturing.

Industry generalizations are deliberately generic to be more inclusive. This generalization often affects the product’s effectiveness and quality. By narrowing the material attributes and design to custom fit the project scope, time and time again, you’ll receive a better product. Furthermore, increased specifications often hold up better under regular use. Custom parts also see increased performance and a longer-lasting product. Finally, using custom parts tailored to your specific needs provides additional savings on unnecessary repair costs. In short, custom-designed parts are better because they were made in such a way as to fit your specific needs.

Structural Ironwork Parts

Structural ironwork frequently uses iron fabrication as reinforcements in construction. Further, steel is an alloy of iron and carbon. Iron and steel fabrication often involves constructing frameworks and metal structures. Multiple construction projects contain the need for heavy metal fabrication.

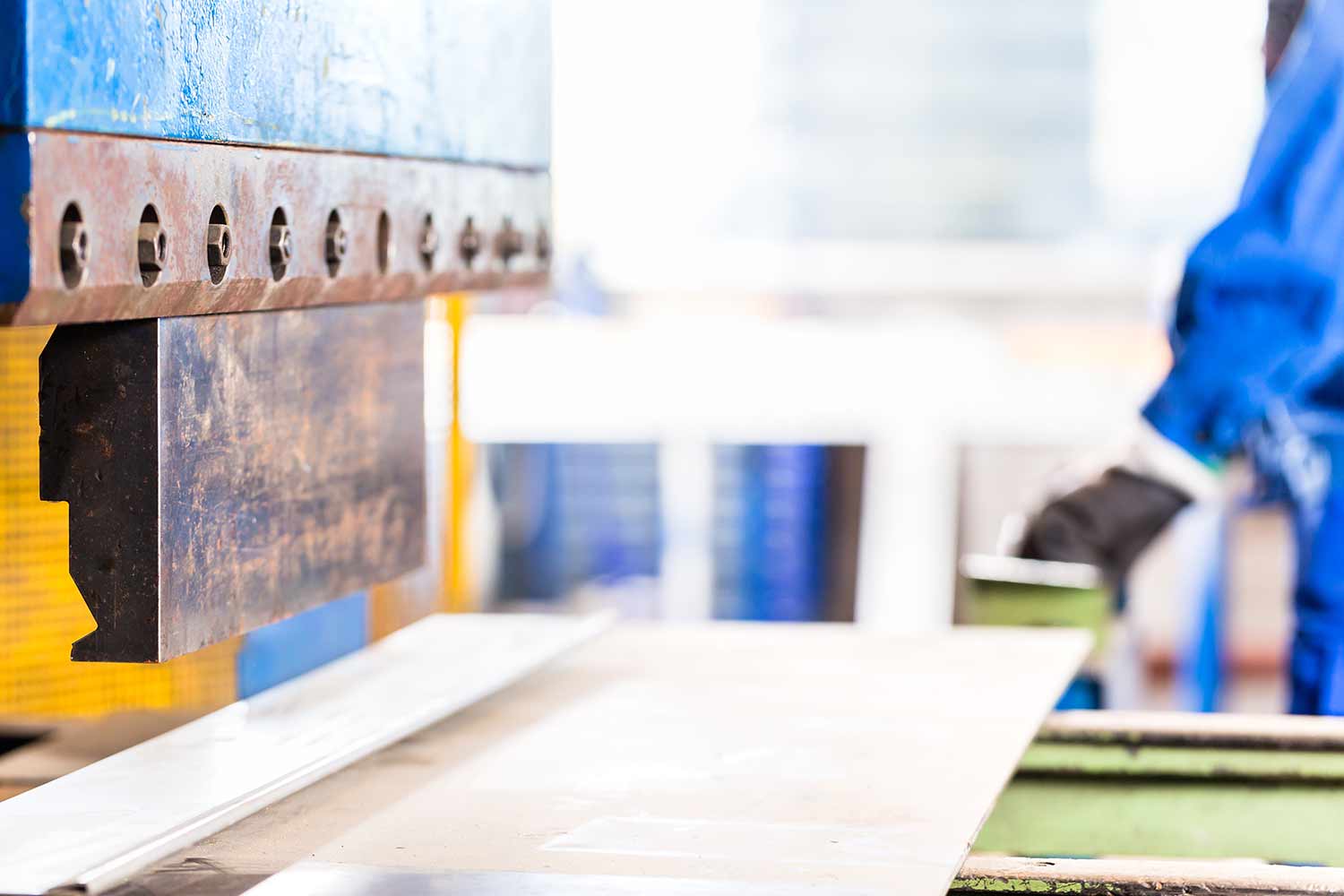

Similarly, structural projects also use iron rods and bars to strengthen slabs, pillars, and building structures. The metal fabrication process bends, cuts, and shapes these pieces into the desired size, thickness, and configuration for the finished metal product.

What is heavy metal fabrication?

Heavy metal fabrication involves larger structures. For instance, staircase, loading docs, and scaffolding, to name a few. Regarding machining projects of this nature, we bend, cut, roll, and weld raw material into the finished product. Some machine shop projects of this size may require onsite measurements for accuracy in your design blueprints. Proform American Manufacturing is happy to send workers out to take professional dimensions and get the job done correctly from start to finish.

Large commercial ductwork, tanks, bins, stacks, and chutes are typical examples of heavy metal fabrication that may use iron or steel fabrication techniques. We’ll provide valuable engineering answers to questions on metalwork fabrication projects of every size and shape.

Professional ironworkers follow safety codes.

Best of all, we are professionals in our field. Proform meets all safety requirements and OSHA standards for structures in or around buildings, including but not limited to stairways and loading docs. We ensure all blueprints for machining ironwork are up to the latest safety standards. Don’t get fined or shut down for unforeseen safety issues.

Proform ironworkers are metal fabrication specialists that care about our customers and their success. We understand that customers deserve safety, and business owners need peace of mind. Therefore, when you hire Proform, you can relax knowing it’s done right from concept to completion. Proform American Manufacturing is your iron fabrication specialist for your next metal product.

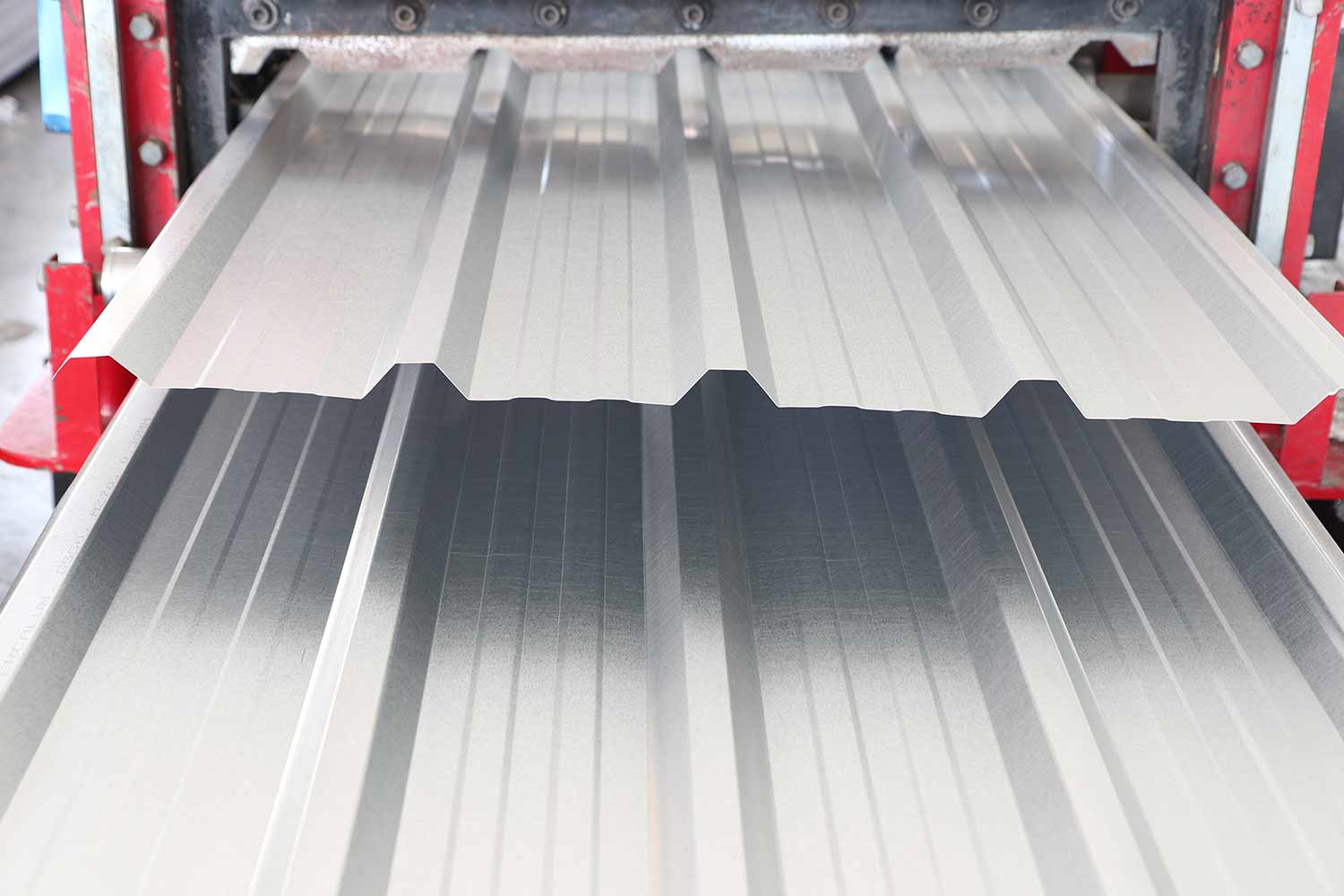

Sheet Metal Fabrication

The most common type of metal used in sheet metal fabrication is steel. Yet, there are essential factors that go into determining which metal is best for your parts fabrication project. Sheet metal fabrication projects consider strength, hardness, conductivity, corrosion resistance, use behaviors, environmental conditions, and length of exposure. These factors determine which aspects play important roles and thus which metal is best for your next custom metal fabrication project.

Carbon steel comes in many different carbon levels.

The higher the carbon content, the stronger the steel. Conversely, lower carbon steel is easier to cut and shape during fabrication. Your fabricators know what metal works best under your project scope and blueprint specifications. Also, we can alter certain metal properties with powder coating and post-production surface treatments.

Custom Machine Shop Concept and Prototype

To begin your custom fabrication design, we meet to consult and discuss the project scope. This discovery meeting is where we deliberate over your specific task details. We outline the desired part’s purpose, function, design, and style. Our team goes over possible solutions, always considering industry codes and regulations and raw material guidelines. We determine the most cost-effective way to achieve optimal results based on your goals. Next is the blueprint phase. Here is where we detail all the precise measurements and specific project attributes. These blueprints go to production for prototyping and then to the metal fabrication process.

Our goal is to create a metal part exceeding all your expectations.

We optimize our product and workflow to get you the very best project at the lowest cost and fastest timetable. Proform American Manufacturing is a steadfast and dependable machine shop. Business owners count on us to get your job done right. We built our reputation on custom fabrications being extraordinary due to a detailed design phase. Your project has to be a perfect fit. We intend on making sure we fulfill that expectation. Trust Proform to come through on your iron and steel fabrication design concept. We make metal parts and metal structures a reality.

Why choose iron fabrication?

- Iron maintains structural integrity under high heat

- Iron and steel are cost-effective metal solutions

- Generally stronger, tougher, and more durable than plastics or soft metals

- Metals allow for a multitude of precision fabrication options to reach your final goal

- Metals can achieve many finishes but often highlight smooth and shiny finishes for a glossy finished look other materials cannot accomplish

- Treated metals hold up to environmental conditions

- Easy to clean

- Higher hygienic disposition than other materials makes it ideal for medical industries

- Metal is malleable, meaning it can be bent and manipulated and still maintain quality and strength.

- Parts can be recycled more frequently, whereas plastics break down. Metals are commonly recycled into other parts indefinitely.

What is iron fabrication?

Iron forming is an iron fabrication process to manipulate cast iron or wrought iron into complex shapes and parts. Manipulating iron uses bending, forming, rolling, cutting, and punching to achieve the desired product.

Iron fabrication, the heavy side of iron fashioning and forming.

Iron fabrication is industrial work, not ornamental. Fabrication of parts often needs welding and serves a specific function rather than being decorative and ornamental. Samples of iron fab are seen all around us in our daily environments. For example, an iron railing for a staircase, ductwork, stacks or silos, even the iron rods used inside the building structure we are currently standing. Iron is a heavy, durable metal ideal for construction and forming.

Does Proform work in stainless steel?

Absolutely. Stainless steel fabrication is a large part of our metal fabrication process. Stainless steel corrosion resistance properties make it ideal for many outdoor or easy-to-clean projects. Proform American Manufacturing works in multiple metals and various metal fabrication shop techniques to reach our customer’s end product results.

We use the latest in metal fabrication technology. Custom fabrication may include cutting & grinding, welding, 3D printing, plasma cutting, surface treatments, and multiple fabrication techniques. As fabrication specialists in our industry, we have the equipment and skill to complete the most complex metal and iron fabrication jobs.

Metal Fabrication Service

Large iron fabrication projects may seem overwhelming to take on. Yet, as a professional metal fabricator, we help guide you every step of the way. We’ll discuss all your fabrication options and recommend best practices. So, don’t feel overwhelmed any longer. We offer our customers practical solutions based on years of experience.

Let us help you get your metal CNC machining project done. The sooner you call us, the sooner we can get involved in solving your problems. As seasoned professionals, we can often relay what looks and works best for your issues. We help clients from conception to completion on projects of all shapes and sizes.