How do I know if Proform’s parts fabrication services fit my needs?

Precision metal fabrication makes large batches of small parts or complex designs and large metal weldments. Further, it can accommodate both custom creations and stock designs. Additionally, some pieces also require assembly. After fabrication, multi-element products are assembled and joined, often welded together for superior joint strength. We use multiple metals to meet client needs, from soft to hard metals and semimetals.

We specialize in metal fabrication techniques:

Plasma Cutting, Forming, Rolling, Ironwork, Welding, Precision Cutting, Grinding, and Punching. We’re experienced in steel, stainless steel, aluminum, brass, copper, and some exotic metals. Finished products often include some surface finishing. Finishing gives the product the proper appearance or adds additional properties to the metal, such as rustproofing.

It takes just a moment to request a project quote.

We have helped many clients with complex metal fab design solutions. Our experience and years of professionalism make us a leading manufacturer. Don’t wonder if you can complete your project. Let us tell you how we will complete it.

Will my part be a raw material or finished product?

Proform American Manufacturing is a full-service parts fabrication factory. Once the metal fabrication process stops, the part moves to additional services to achieve the detailed specifications for the finished product. We perform many fabrication services in-house, while others are through our select trusted partners. Nonetheless, we ensure you’ll get the parts completed to your satisfaction and end-product specifications.

Finishing services such as deburring, heat treatment, polishing, painting, bathing, and coating treat the exterior to achieve the desired looks or characteristics. You’ll get everything completed in one run by choosing Proform Manufacturing. Proform American Manufacturing completes the job from concept to completion.

Small Precision Parts Metal Fabrication

Small parts are for large runs of hundreds and thousands of products. The project scope may be a customized industry design or commercial standard production parts. The intricacy of the plan depends on the parts function and industry needs. We work with small complex pieces for the medical, electronics, military, transportation, and recreational industries, to name a few.

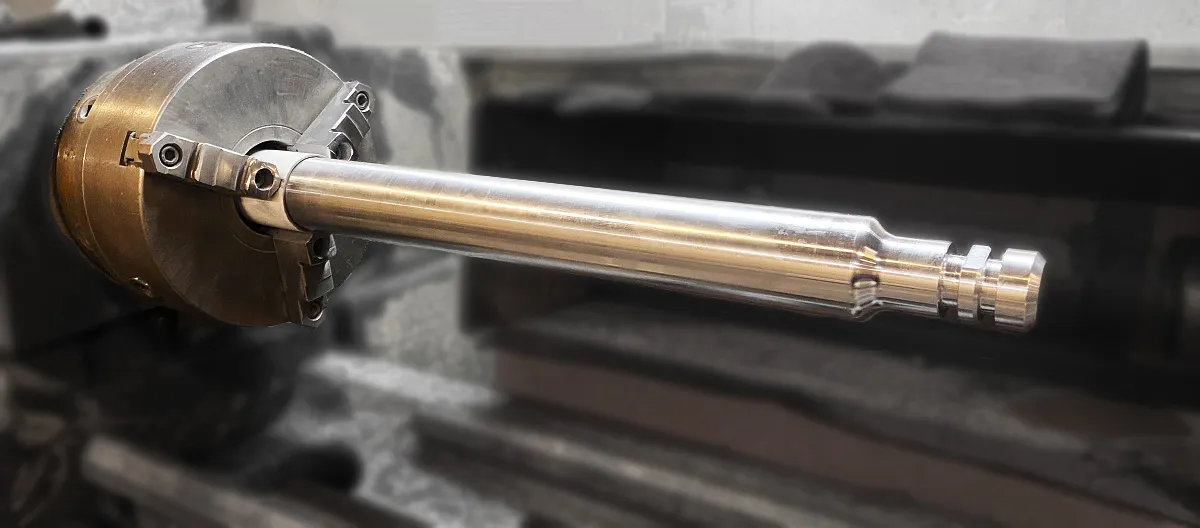

Swiss cnc precision machining is a technique the metal fabrication industry uses for small sophisticated components. This method creates highly intricate detailed parts with extremely high tolerances for accuracy. The Swiss machining name derived from the well-known meticulous precision of Swiss watch-making techniques. This method maintains a tolerance of 5/1000’s of an inch during production. For perspective, that is less than the diameter of a single human hair.

Swiss CNC machining services are known for the highest tolerances in the CNC machining industry.

For this reason, medical devices and electronics often use Swiss fabrication. For example, those tiny parts inside a pacemaker, dental implants, and even those miniature screws inside your laptop or iPhone. These are all prime examples of metal fabrication created using Swiss custom machining.

Industrial fabrication includes foraging metal sheets into integrating various parts for assembly. The finished product is usually massive in scale. Industries that commonly use metal plates include heating & cooling, automotive, aerospace, oil & gas, energy, farming, and mariners.

Sheet metal parts are bent, cut, welded, and shaped together. Metal fabricators manipulate the metals to your specific design specifications. A prime example of the industrial metal fab is the heating and cooling ductwork used in buildings and common structures. Sheet metal fabrication is also typically used for large metal sheet pieces such as car parts.

Similarly, structural engineering produces large-scale products used in construction and structural designs. Metal structures often require durability and strength to ensure safety codes and regulations. For example, walkways, staircases, scaffolding, and more have safety codes to maintain building safety.

Yet, structural metal fab can also include structural components used in the building’s framework. Such as rods to support concrete or beams and joists, not to mention metal joints and plates. Construction industries use a lot of metal fabrication and iron fabrication services, accounting for $27.5 billion in shipments. T. Proform American Manufacturing is a proud metal fabrication service provider.

One added service Proform American Manufacturing offers when needed is an onsite measurement for large structural metal fabrication. Metal production of this size often needs to accommodate the specifications for the intended part and the structure it attaches to. When required, a custom fabricator creates detailed drawings with exact measurements. This additional step eliminates miscommunication and assures business owners that the fabricated structure fits precisely as intended.

Indiana is one of 8 states that combine to produce over 1/2 of all the metal products fabricated in the US.

The main benefit of a metal fabrication shop such as Proform American Manufacturing is the multitude of services we provide. We pride ourselves on being your one-stop-shop for all your metal fabrication needs. Our process cuts down on frustrations for business owners working with numerous vendors and multiple timelines to complete a complex fabrication project. Business owners no longer lose hours tracking the progress of one fabrication step to the next. Proform American Manufacturing takes on the project and sees it through to completion.

Hiring Proform eases your concerns and reduces wasted hours. We watch over every step of the process to ensure the quality and timeliness of your project. You’ll no longer chase multiple project heads with various companies to get answers and a final product delivered to your door. When you hire Proform, you’ll work with one company and get the product delivered on time and without worries.

Our fabrication shop often works simultaneously cutting and shaping. Therefore, we also reduce timeframes and meet tight deadlines. Get answers to all your metal fabrication questions. Learn more about Proform American Manufacturing.

What is metal fabrication?

Custom metal fabrication starts with a concept developed for premium performance and industry requirements-a professional fabricator drafts detailed blueprints with the help of computer-aided drafting software. Metal pieces are cut, shaped, and molded to fulfill the project scope details. The end product is precision quality perfection.

Two Forms of Metal Fabrication

The metal fabrication process constructs an end product from raw materials. The metal part is either formed from a solid block of raw metal or printed in a 3D printer.

Removing excess metal from a solid block of material is known as ‘machining’. Machining places raw material into a machine where it turns and is trimmed and cut down to shape and size. The precision machining process often uses the aid of CAM (computer-aided machining) software. Consider the surfacing process like a sculptor slowly removing the clay from a solid block to get the desired shape.

In this case, Proform American Manufacturing has top-performance 5 axis machining doing the sculpting. 5-axis machines are considered the cream of the crop in metal fabrication technology. This technology allows us to simultaneously cut, shape, and manipulate the metal on five separate axes. Hence, we’re reducing the workload and the customer’s timeline. Consequently, machining whittles down the metal to precision accuracy to fit the project specifics and get your intended shape with exact measurements.

Similarly, the 3D printing metal fabrication process builds up your modeled part layer by layer to achieve the desired end result. Metal powder is layered together during the printing process and bonded. This action affords more design flexibility. 3D printing produces more complex designs following CAD (computer-aided design) specifications. Additionally, the 3D printing process delivers a metal part that is strong and durable, as well as complex.